Our AgBots might sound like sunshine and rainbows, but do they actually live up to those expectations? At Agritechnica 2023, we hosted four lunches, where our customers talked about their experience and everyone had the opportunity to ask questions. Customer satisfaction is our number one priority, since they are the ones who will eventually use the AgBot every day.

In case you missed it or want to read more about customer experiences, we will share a summary of these four lunches in this blog post.

AgXeed

Communications

Lunch #1

The first lunch was on Sunday, where Jens Bothmann and Volker Hack were our special guests. Bothmann owns the AgBot T2, but he is contemplating of also integrating the W4 into his farm. He has a lot of grassland, that is why the four wheeled AgBot is a very attractive option, since it will perform turns on the headland even more delicate then the T2 with its rubber tracks. Bothmann says he uses the T2 for arable applications and has even done two applications at once. Mulching and planting cover crops using an electrified mulcher in the front and a simple-box drill in the back works perfectly together. He is now planning on using the AgBot for the next task he needs to do, which is rolling.

A very important comment of Bothmann is that you need at least one capable dedicated person with a proactive and assertive mindset who is willing to dive into this new technology and how to use the AgBot to its full capacity. With time and experience even more use cases unfold, increasing the utility of the AgBot even further.

It’s very easy to use, even for me”, Hack laughed. Hack also mentioned that a funny thing he experienced since the purchase of the AgBot, is while he is doing work in the field himself on a tractor, he now thinks “how would the AgBot operate in this field?” instead of “how should I do it?”. In terms of field operations, he has no co-workers right now, and it is very hard to find the people for the job, especially when they are slow and time-consuming and need to be done very precisely. The AgBot can easily perform these kinds of tasks with high precision. Besides, the minimum field size for the AgBot to operate in his opinion are 2 has, if the operations are intensive and slow.

Lunch #2

The next day, Monday, we were happy to have Volker Hack join us again for a customer lunch, along with Harm Kalfsbeek, who owns one machine since June/July 2023. Kalfsbeek would definitely agree with the statement of Bothmann that you need someone who is dedicated to figure out how the AgBot works and admitted this as his biggest challenge currently. Kalfsbeek said that he first wanted to understand it himself, so he first operated the machine for a while himself, but now he has to pass it on to his workers. He is convinced that this technology and system is the future of farming, the way to reduce soil compaction and the challenge to finding qualified personnel. The implements Kalfsbeek uses are for instance a 5-meter disc cultivator and a 4-meter tine cultivator. Hack and Kalfsbeek both agreed that the fuel consumption used by the AgBots is 10% less compared to a traditional tractor. A reason for this, is that the AgBots have a very efficient drivetrain, but Hack also claimed that the AgBot also saves fuel because he can let it can work slower in some applications where speed is not decisive for the working results.

Statements day 1 & 2:

- AgBots are easy to use

- Takes about 15 minutes to load the AgBot off the trailer

- Less fuel consumption using an AgBot

- Dedicated operator is preferred

Lunch #3

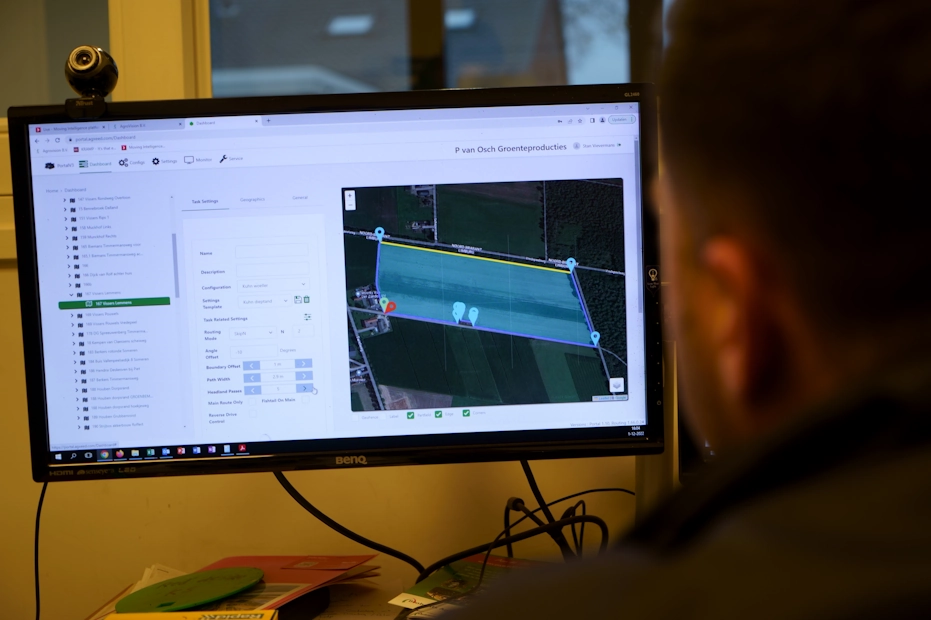

Tuesday was already the third day of hosting the lunches with farmers. Harm Kalfsbeek and Stan Vievermans joined us this day. Stan Viervermans is the operations manager at P. van Osch Groenteproducties, a vegetable grower in the Netherlands, very close to the location of AgXeed. Vievermans mentioned that at the company, in most years, they were not able to finish all the tasks that need to be done in the season since time is limited, however they managed to complete everything this year, thanks to the AgBot. The AgBot can perform unsupervised non-stop work day and night, even in harsh weather conditions. These two reasons enabled van Osch to complete all the tasks they wanted within the season.

With setting templates available, after the settings are known and proven in reality they can be copied to other tasks, while still giving the option to do the fine adjustments in the field with the remote control. Vievermans said that they are looking forward to owning more machines, and also adding the rest of their fleet to the AgXCloud, and managing & planning entire operations in the system.

Statements day 3 & 4:

- AgBot performs unsupervised non-stop work day and night

- Works in harsh weather conditions

- Planning a task is done in 1 minute

- Dedicated operator is preferred

- Learning quickly through experience

Lunch #4

On Wednesday, the final day of hosting these lunches, we had a co-worker of Bothmann, Christian Kutzner who is mainly operating the AgBot. He experienced some challenges with the AgBot but got used to the procedure of working and adapting his own work to operating an AgBot. He mentioned that you learn quickly through experience and working the AgBot. Many improvements have been made since then. They are still looking for more operations to be done by the AgBot to maximize the utilization and therefore further improving the AgBots economical value, while expanding the options from an agronomic perspective.

Facts & figures:

- Hosted 4 lunches with customers

- 6 customers sharing their experience

- Many questions answered

- Lots of finger food served

We want to thank all of our customers for sharing their experiences and answering all kinds of questions during these lunches.